Product Overview

The Acoustic Imaging Camera combines acoustic images with video footage captured by a camera mounted on a microphone array, presenting a transparent overlay that allows for intuitive analysis of the tested object's condition. Utilizing acoustics, electronics, and information processing technology, this technique transforms sound into visible images, aiding users in comprehensively understanding sound fields, waves, and sources. It facilitates easy identification of the origins and causes of noises and vibrations in machinery, reflecting the operational stateof the device.

With the aid of sound source imaging technology, it converts the received sound into a visual display, allowing you to quickly locate the source of the problem. Its high-frequency feature enables early detection, assisting in the prompt development of maintenance plans. This is why the YS-acoustic imaging camera has a frequency range of 2K-80KHz.

Key Features

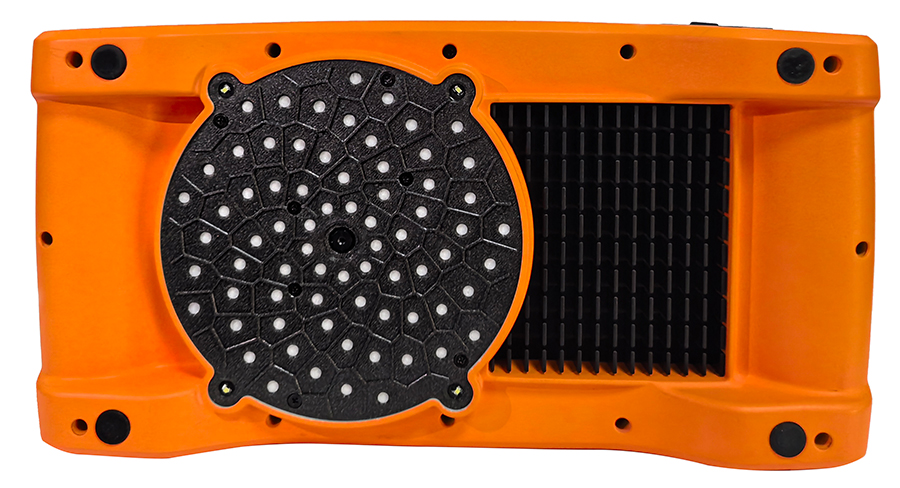

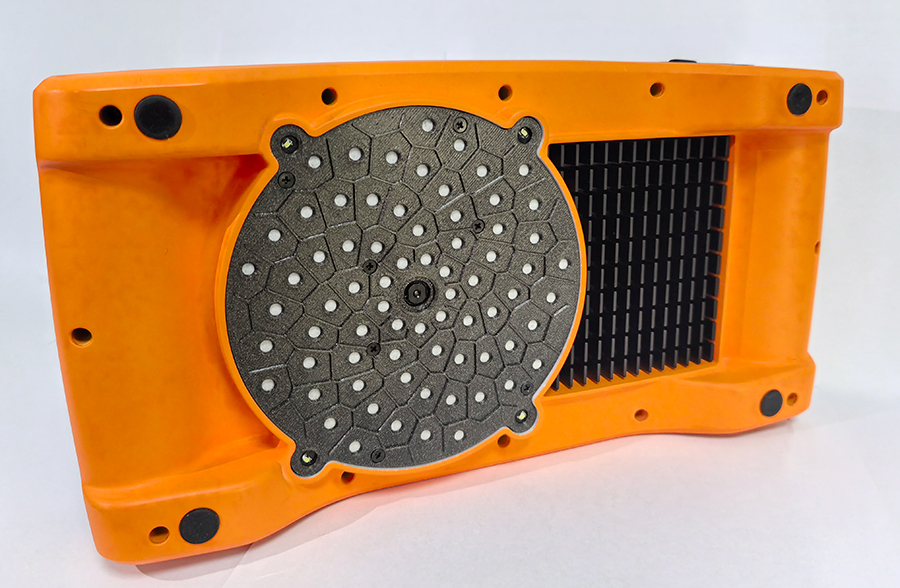

* Available for use with one or both hands, featuring an integrated design that combines sound and imaging.

* Compact, lightweight, and portable design enables quick and straightforward operation.

* Capable of extended, continuous monitoring across a broad frequency range, covering both audible and ultrasonic sounds.

* Delivers rapid and stable imaging, efficient performance, instant visualization, and quick identification of fault points.

* Provides real-time, high-speed acoustic imaging and listening across the full frequency band with frequency filtering, including a storage mode for data recording.

* Supports comprehensive channel data recording, image and video storage, and playback.

* Offers time-frequency domain processing of acoustic signals.

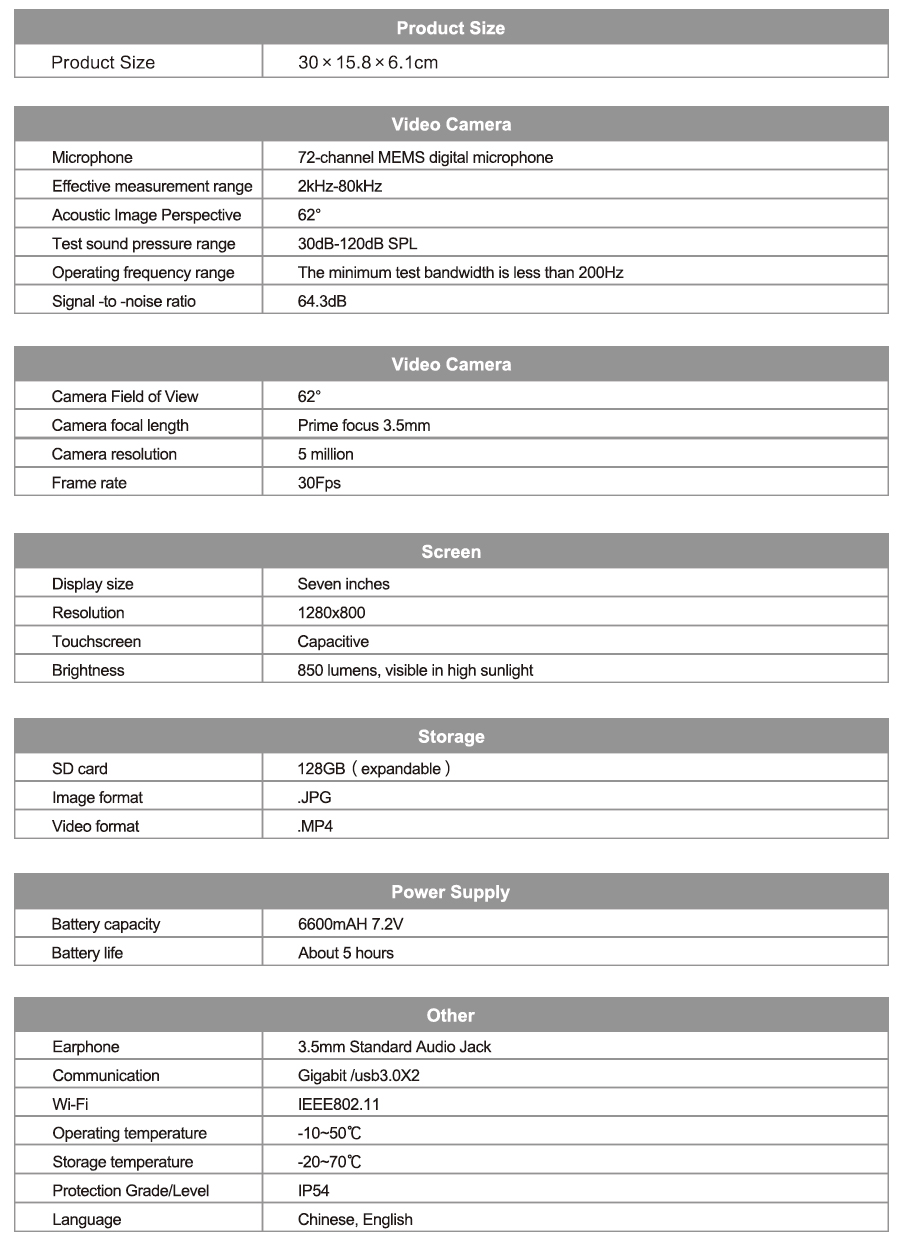

Technical Specifications

Application scenarios

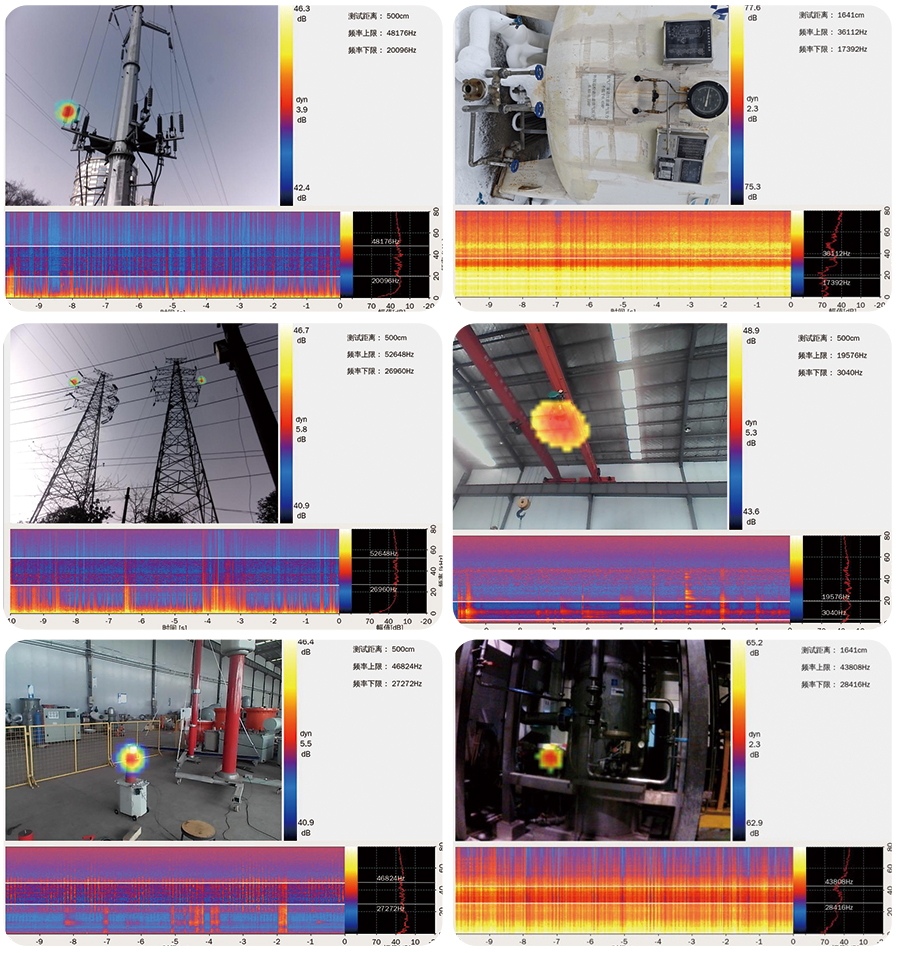

Ultrasonic acoustic imaging technology is extensively applied in scenarios such as pressurized or vacuum conditions for gas leak detection, airtightness testing, partial discharge detection in electrical facilities, mechanical structure noise analysis, and noise source localization.

In the manufacturing field: The device can be applied for quality control, monitoring, and analysis of the production process. It is useful for defect detection and quality analysis during casting, welding, splicing, and other processes. During production, it allows for the monitoring and analysis of product logistics, noise, vibration, pressure, and other indicators, thereby ensuring the stability and consistency of product quality.

In the energy sector: The device is applied in oil and natural gas exploration, power equipment testing, and maintenance of wind power generation equipment. For example, in oil and natural gas exploration, the acoustic imaging camera can be used for downhole image capture and data analysis. In power equipment testing, it can be applied for fault diagnosis of high-voltage cables, transformers, and switchgear, enhancing the safety and reliability of electrical equipment. In the maintenance of wind power generation equipment, it can be utilized for the inspection and fault diagnosis of large blades.

In the environmental field: The device is used for gas leak detection, noise management, water quality monitoring, and pollution source localization. For example, in gas leak detection, the acoustic imaging camera can identify and detect leak points in facilities such as oil and natural gas pipelines. In noise management, it can be used to analyze and locate vehicle and machinery noise. In water quality monitoring, it applies to the localization and monitoring of pollution sources in rivers, lakes, and reservoirs.

In other fields: The application of acoustic imaging cameras spans a variety of industries including petrochemicals, metallurgy, electricity, machinery, automotive manufacturing, electronics, defense, and scientific research. For instance, in mechanical manufacturing, it is used for assessing product sound quality; in the energy and power sectors, it helps in the localization and investigation of leaks, partial discharges, and mechanical failures; in environmental monitoring, it assists in noise localization and early warning; in public transportation, it captures illegal honking and street-racing noises.

Application field

The device is utilized for various forms of partial discharge (PD) detection and localization, including arc detection, trace detection, and corona detection. It is used for PD testing in electrical equipment such as transformers, switchgear, ring main units, cable ends, insulators, circuit breakers, busbar tubing, reactors, power cabinets, and communication cabinets. Additionally, it serves in detecting leaks in pneumatic systems and identifying mechanical failures.

Petrochemical industry application: The device is utilized for monitoring pressure and vacuum leaks, bearing surveillance, and steam valve operations. It is effective in detecting internal leaks in valves, assessing compressors, heat exchangers, gears, gearboxes, pumps, and motors, as well as evaluating the integrity of pipelines and tank seals.

Electricity and electrical applications: The device is employed for leak detection in the air-cooled island systems of thermal power plants, long-distance leak detection in air-cooled islands, remote detection of high-voltage gas leak points, as well as vacuum and negative pressure leaks.

Other typical applications: The device is used for monitoring bearing lubrication, engine operation, cavitation in electric pumps, motor function, and compressor performance. It detects lubrication failures in operational equipment, checks for pipeline and conduit leaks, and assists in identifying and troubleshooting general mechanical faults.

Application

Compressed Gas and Vacuum Leak:

- Compressed Air Leak Detection

- Carbon Dioxide Gas Leak Detection

- Pneumatic Drive Component Inspection for Industrial Robots

- Nitrogen Gas Leak Detection Case

- Natural Gas Leak Detection

- Refrigerant Leak Detection

- Mixed Oil and Gas Pipeline Leak Detection

- Vacuum and Negative Pressure Equipment Leak Detection Case

Partial Discharge Detection:

- High Voltage Electrical Equipment Insulator Discharge Detection

- Partial Discharge Detection for 10kv Line Ceramic Crossarms

- Partial Discharge Detection for High Voltage Electrical Equipment Connectors

- Internal Equipment Partial Discharge Detection in Electrical Cabinets

- Internal Equipment Partial Discharge Detection in Transformer Cabinets

- 35kv Switch Cabinet Secondary Meter Head Partial Discharge Detection Case

Airtightness Testing:

- Tank Product Airtightness Testing

- Wind Turbine Blade Bracket Airtightness Testing

- Airtightness Testing of Polymer Membrane Production Equipment

- Turbocharger Airtightness Testing

+86 4000-198-196

+86 4000-198-196

Hotline

Hotline