Features:

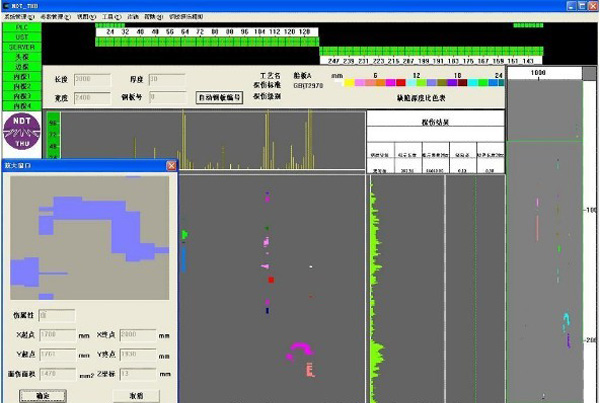

• Independent multi-channel ultrasonic pulser / receiver cards, high-precision, high performance ultrasonic signal acquisition and processing card (up to 100MHz bandwidth, 12-bit precision).

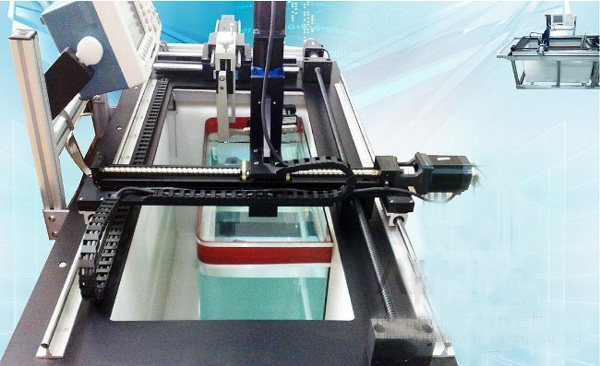

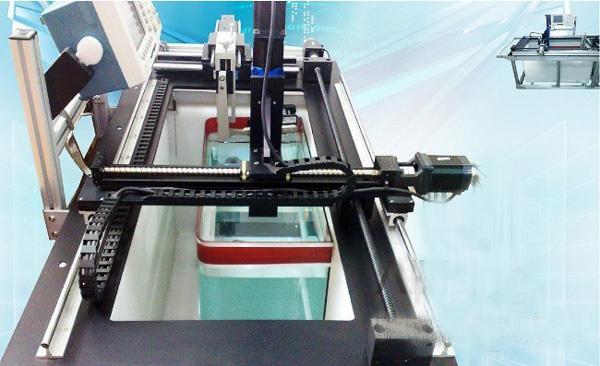

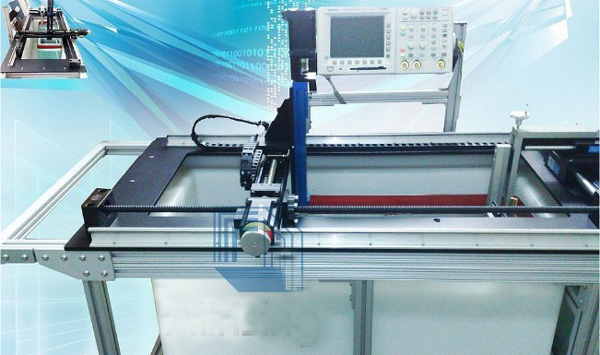

• European companies use British Villa (TRIO) multi-axis motion control card, both with 3-6 axis control.

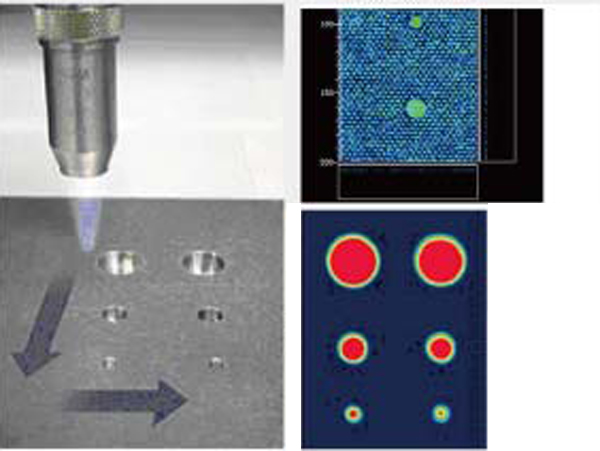

• by high-performance multi-axis CNC motor drive, multiple degrees of freedom (3-5), high-speed (up to 500mm / s), precision (positioning accuracy of 0.02mm) tank desktop scanning system.

• trace can be realized by CAD files (including three-dimensional) scanning, according to custom (produced) track scanning, manual control scanning

• PXI-bus computer system fully functional set of multi-dimensional surface contour tracking with scanning, automatic defect recognition, location, quantitative analysis, automated ultrasound imaging in one of the A / B / C scan expert system software.

Typical Applications:

Laboratory studies of scientific research institutes, aerospace, automotive, military, petrochemical, power and other industries disk ring, cast parts, composite materials (such as carbon fiber, honeycomb, etc.) and other complex-shaped surface of the work piece detection

+86 4000-198-196

+86 4000-198-196

Hotline

Hotline