No longer difficult to inspect workpiece that with complex materials and structure

LUS-5000 Laser ultrasonic scan system is a nondestructive inspection system, which can be used to study the ultrasound propagation in an arbitrary-shaped object, and also be used to the nondestructive inspection of materials and structures.

【Feature】

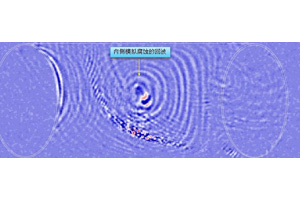

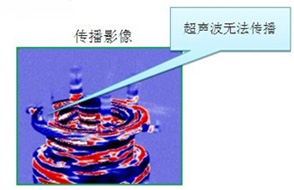

◇ Visualize the ultrasound propagation process

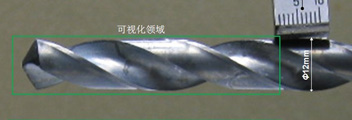

◇ Used to study the ultrasound propagation in an arbitrary-shaped object

◇ Used to the nondestructive inspection of materials and structures

◇ found the defects in object easily in a short time

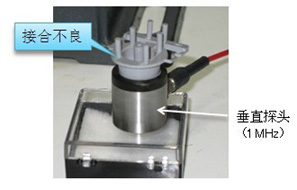

◇ Used to evaluate the ultrasonic probe, the structure health and the material performance, etc.

【Standard Specification】

◇ Visualization range:Within ±20°

◇ Channel number:2

◇ Distance to object:0.1m~2m(using focus lens: ~ 10m )

◇ Scanning speed:Max.2kHz( 200x200 scanning points in 20 seconds for CFRP)

◇ Laser :Max.3 mJ@1kHz、1053nm pulse YLF laser

◇ Pulse duration:20 or 30 ns

◇ A/D sampling rate:Max.250MS/s

◇ Display image:Ultrasonic propagation moving image, B-scope image (speed image ), A-scope waveform etc..

◇ Moving image speed:1~30 frame/s ( variable ).

◇ Inspection object: metal, ceramics, resin, composite material, etc..

◇ Inspection thickness:about 0~100mm(metal)

◇ Inspection precision: about 0.5mm

【Main Application】

◇ Flaw detection for pipelines of petroleum, gas, power plant etc.;

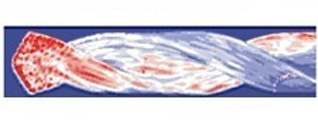

◇ Inspection of fatigue damage, internal defect, weld defect, cracks in composite material, etc.;

◇ Study of wave propagation mechanism, performance evaluation of ultrasonic probe, structure health evaluation, material evaluation, etc..

【Application Field】

Automobile, aircraft, power plant, shipbuilding, petroleum, gas, iron manufacture, electronic component, semiconductor, etc..

LUS-5000 Laser ultrasonic scan system provides strong functional software on image and signal analyses. Using this system, the ultrasound propagation process can be observed on line. Then defects can be found easily on a display of computer. As a new useful tool, unprecedented before, it can analyze and evaluate defects. In order to research on non destructive inspection in universities or institutes conveniently, we can provide the software only, no whole system for you.

Propagation_Process_Image

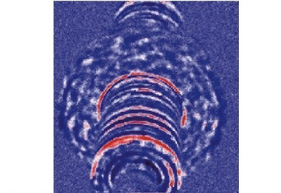

Max_Amplitude_Image

Examples:

Ispect service:

In order to meet the need of not long-term needs customer, we also provide We also provide service of inspect workpice by this system services, fees according to the workload.

Free charge trial to confirmed effect:

In order to understand LUS-5000 Laser ultrasonic scan system more well by users in enterprise, university, laboratory, etc., we will support a free experiment for their sample or product at the first time. In this case, transportation charge of the sample should be paid by them own.

Welcome to provide workpiece that difficult or slow to inspect by traditional method to us to confirm it can inspect by this system.

+86 4000-198-196

+86 4000-198-196

Hotline

Hotline